Blog

As a leading U.S.-based trash bag manufacturer, Greenwayplastics operates with strong production capacity and fully equipped machines to produce 100,000+ bags daily. and provide wholesale supply, as well as OEM and ODM services. Next, we’ll walk you through the trash bag manufacturing process so buyers can better understand how to choose the right factory and customize their own branded trash bags.

Raw Material Preparation for Trash Bag Manufacturing

The main raw materials used for making trash bags are PE, LDPE, and HDPE. These normally look like small white pellets. When we prepare to produce, for example, 10-gallon trash bags, we load the pellets into our production line and add several additives—such as toughening agents, which help make the bags stronger and more tear-resistant. After adding all materials, everything is thoroughly mixed before moving to the next step.

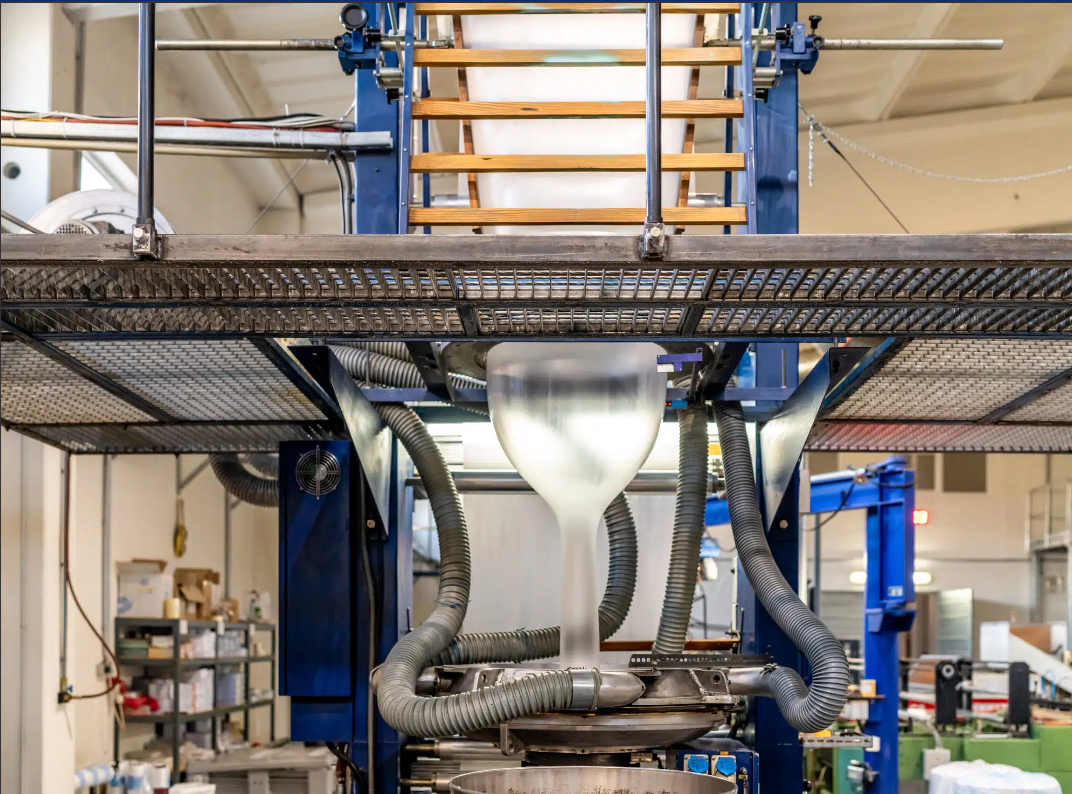

Blown Film — The Core of the Trash Bag Manufacturing Process

Once the mixed materials enter the extruder, the machine heats them to different temperatures at each stage. At around 200°C, the plastic pellets melt into a uniform liquid. The molten plastic is then pushed through a circular die to form a tubular film. Air is blown inside the tube—like inflating a balloon—while the film is pulled upward and cooled. This process creates a smooth, uniform plastic film. If your trash bags need custom printing or a logo, this is the stage where the printing is applied.

Bag Making — Turning Film Into Finished Trash Bags

When the film rolls are ready, they move to the bag-making machines. Here we perform: Sealing and cutting, Perforating and rolling, Counting and packaging preparation. This allows us to produce different styles of trash bags, such as: Flat bags, Roll bags with perforation, T-shirt bags, Small household bags, like 2-gallon trash bags, Large commercial bags, like 32-gallon trash bags

Quality Inspection by a Professional Trash Bag Manufacturer

Next, as a professional trash bag manufacturer, we conduct a thorough inspection to verify: film thickness, tensile strength, seal strength, and overall appearance. These factors directly impact the user experience, so we ensure every bag meets our strict quality standards. At Greenwayplastics, our mission as a leading trash bag manufacturer is to make delivering reliable, high-quality products our top priority.

Packaging and Global Shipping

After the bags pass inspection, they are packed—typically 50 or 100 pieces per case, or customized according to customer requirements. Labels, barcodes, and product information are added, then the cases are palletized, stretch-wrapped, and prepared for shipment.

Conclusion

Because of our professionalism, responsible attitude toward customers, and commitment to producing high-quality trash bags, we’ve earned major orders—including supplying Walmart-branded trash bags. This experience reinforces our reputation as a trusted trash bag manufacturer.